Maintenance Roll Cutter

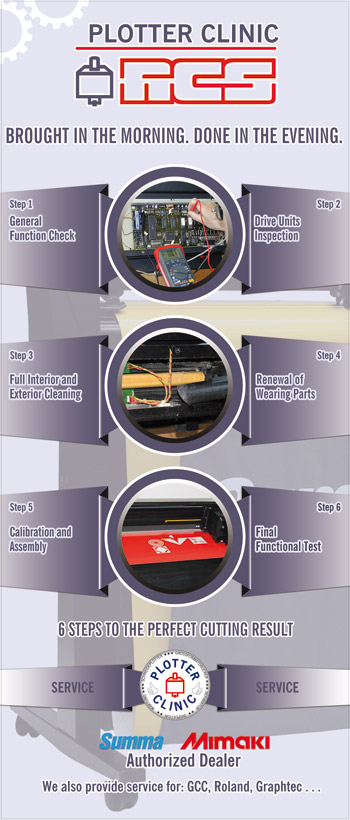

Maintenance is the important major inspection of your cutter to maintain its functionality, to detect defects at an early stage and to eliminate them. Thus, maintenance helps to avoid higher follow-up repair costs for your cutter in the long run.

Roll cutter maintenance includes the following tasks:

Function test

- Interface

- Machine parameters such as pressure, offset

- Self test

- Firmware update (if necessary)

- Calibration of the cutter head

- Length calibration

- OPOS calibration (if present)

Identification and replacement of the parts to be renewed*

- Inspection of the drive units

- Cutting quality

- Drive belts for foil transport

- Cutting strip

- Pinch rollers

Cleaning

- Interior cleaning

- Exterior cleaning

- Cleaning the transport shaft from adhesive residues

Small Inspection Roll Cutter (up to 24")

A small inspection should be performed at regular intervals at a specialist workshop.

A small inspection includes the following tasks:

Function test

- Interface

- Machine parameters such as pressure, offset

Visual inspection

- Drive units

- Cutting quality

- Drive belts for foil transport

- Cutting strip

- Pinch rollers

- Transport shaft

Carrying out minor maintenance work

- Depth adjustment of the blade

- Replacement of the cutting strip*

Cutter repair – Cutter maintenance – Cutter service

*) Parts are replaced after consultation with the customer. Only original spare parts are used.